Animation System Revamp Summary

As of 2018, the La Cañada Flintridge rose parade float’s animation system is nearly 20 years old. As the system continues to age, components that are no longer manufactured are slowly beginning to fail. Starting in 2017, I began work on a replacement.

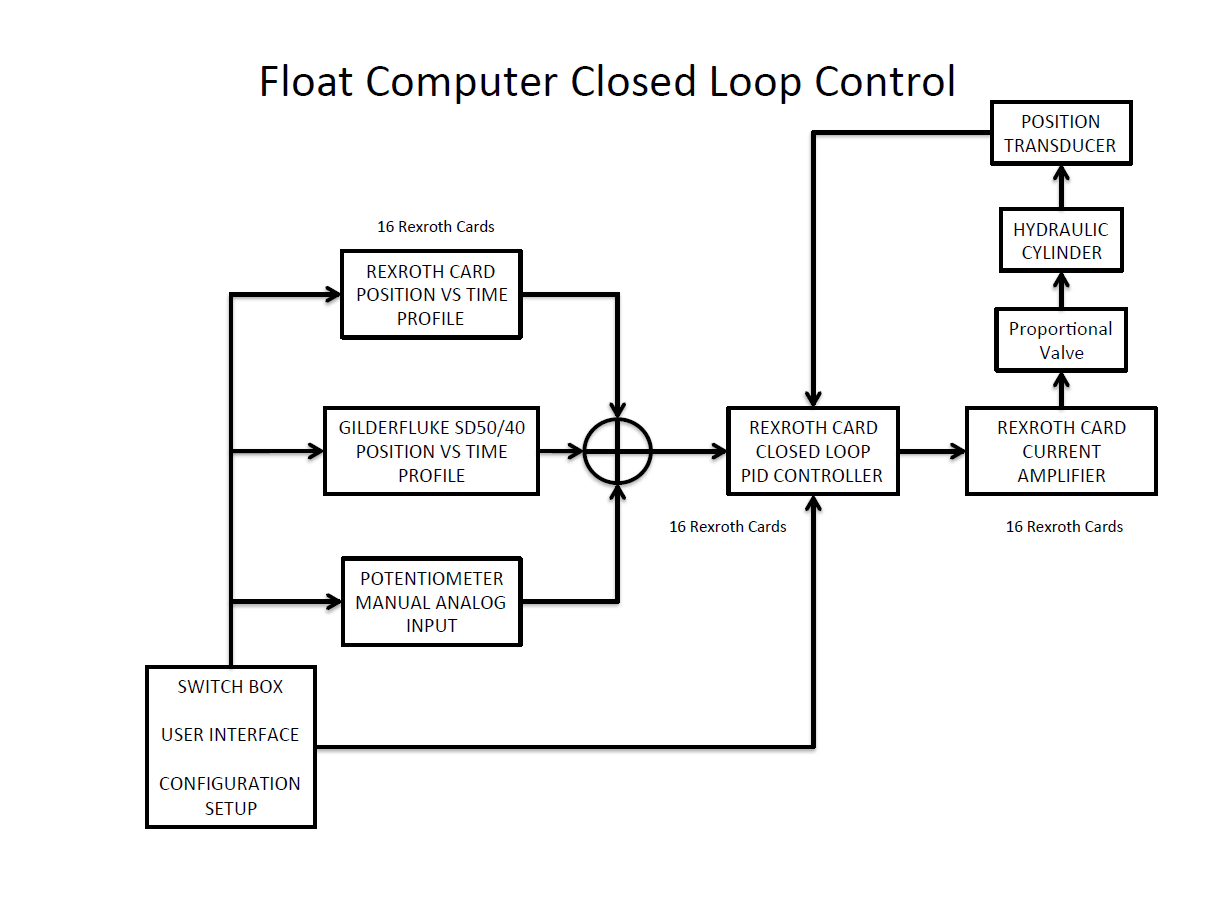

The original system is based of off Rexroth hydraulic control systems interfaced with Gilderfluke show controls. The Gilderfluke Sd-50/40 is responsible for providing synchronized position data for the float’s animation elements, as well as audio for the float’s sound system. The position data is sent to a Rexroth closed loop control module which then actuates hydraulic valves to move various animation mechanisms on the float.

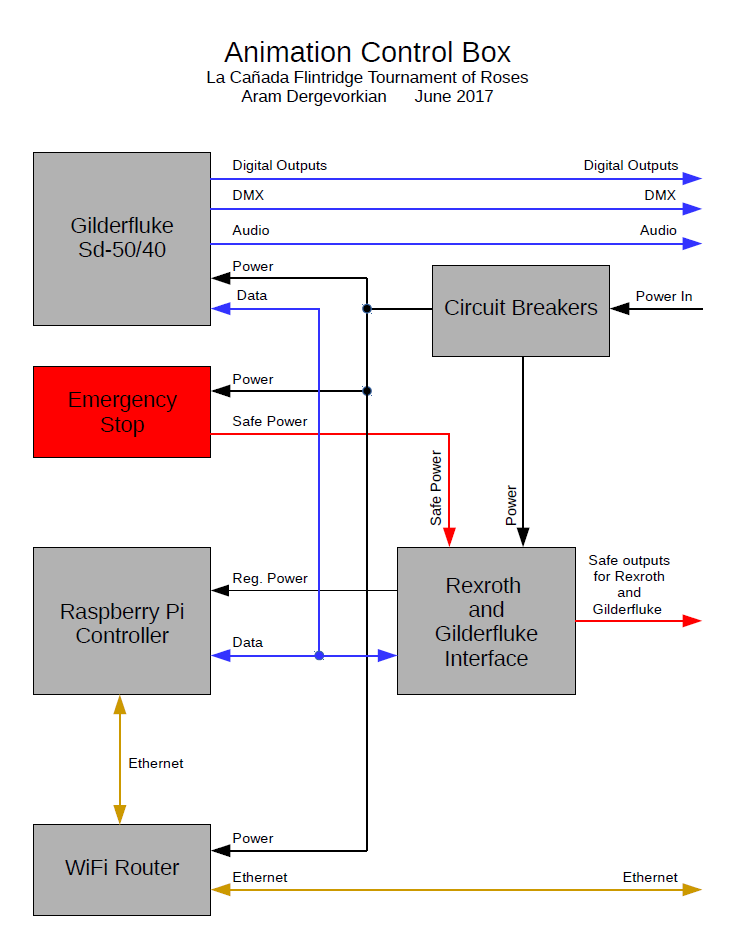

The system has been redesigned to operate using the same Gilderfluke Sd-50/40 for overall animation show control, but there are rather drastic changes to the user interface and the way control tasks are divided. Unlike the previous animation system, the animation system is separated between 5 boxes, a single main control unit, and 4 separate “valve bank modules”. The main controller is kept in the animator’s compartment on the float, and is linked to each of the valve bank modules which can be mounted wherever they’re needed on the float.

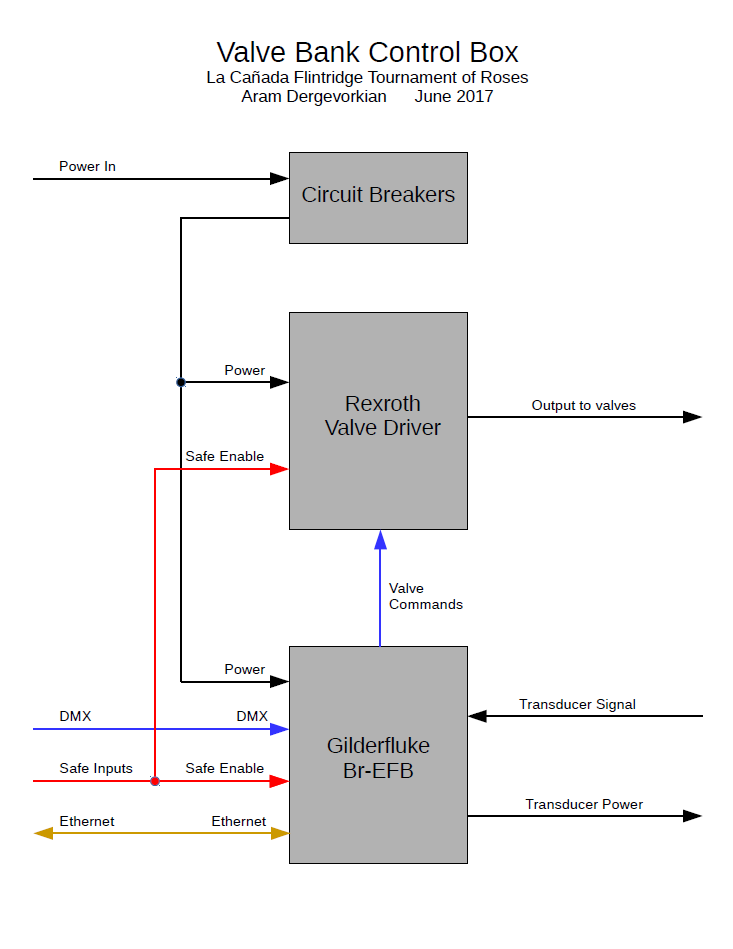

The new animation system functions in a somewhat similar manner to the old one, though responsibilities are shared slightly differently between the Rexroth and Gilderfluke systems. In this system, closed loop control functions are carried out using a Gilderfluke Br-EFB; the Rexroth valve driver modules only serve to amplify the control signals from the Br-EFB to drive our Rexroth proportional hydraulic valves.

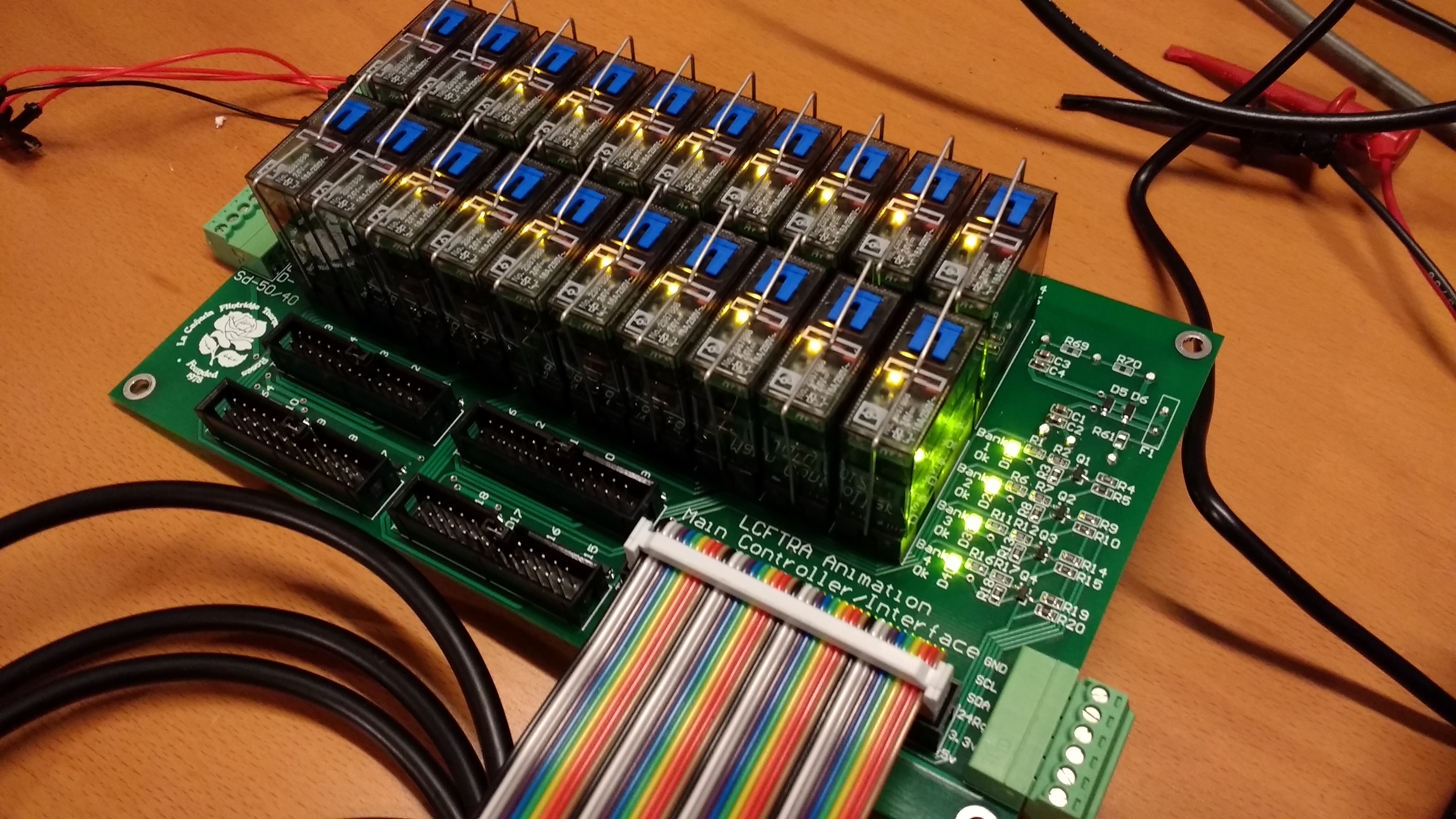

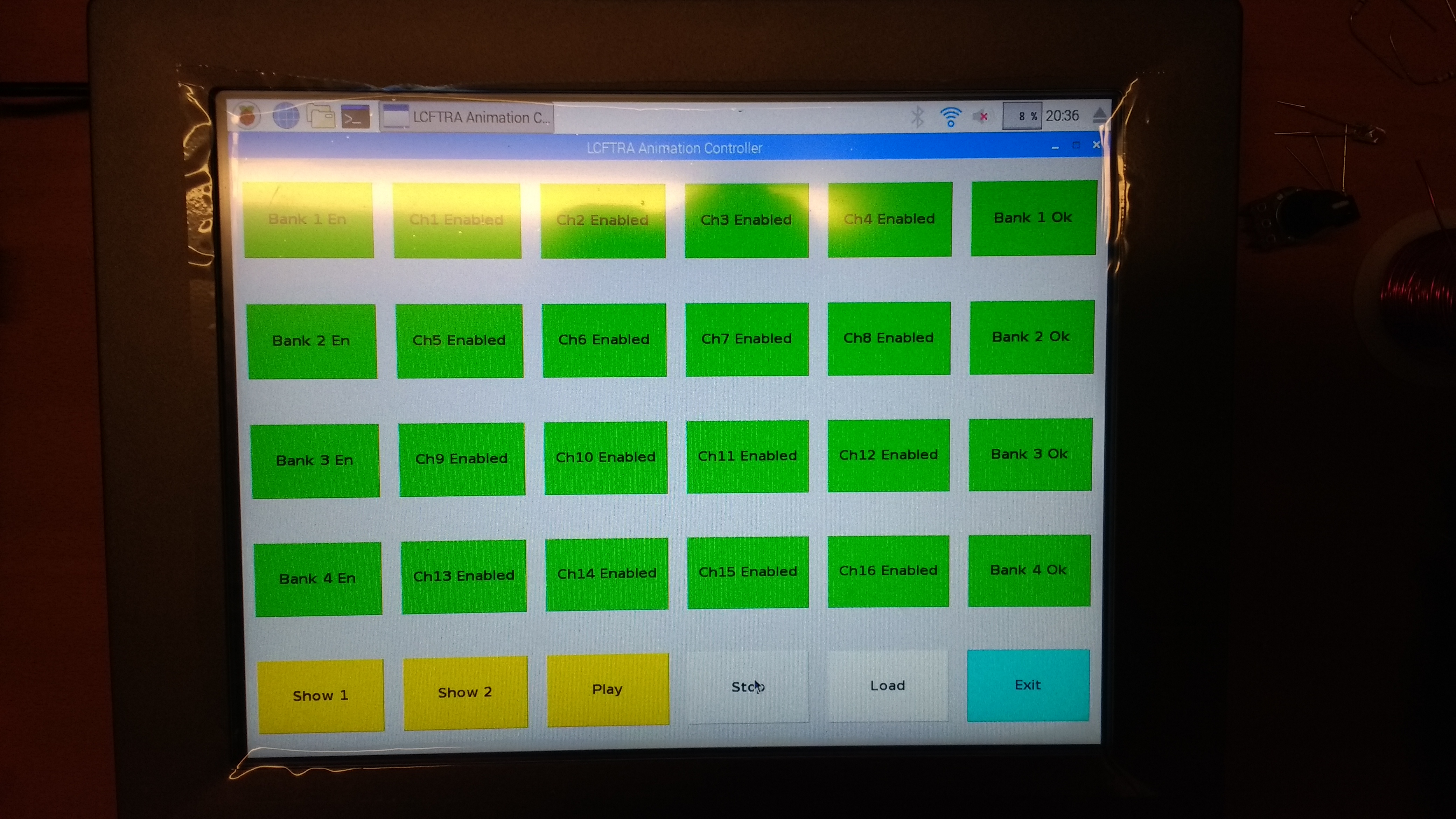

Another significant update to the animation system is the user interface. Instead of a box with quite literally over a hundred switches, the system will be controlled by a computer that interfaces with hardware through a custom designed PCB.

The animation computer will be controlled using this 12” industrial waterproof touchscreen. The integration of a touchscreen and computer into the animation system not only allows for a simplified user interface, but also allows for testing, debugging, and calibration of the system without an external computer thanks to the Gilderfluke Br-EFB’s networking capabilities.